|

|

|

|

|

|

|

|

| |

|||||||

| |

|||||||

| |

|

|

|

|

|

|

|

Temperature Range

Heat Pipes are available in two temperature ranges.

For Injection Moulds: Heat

Pipes having temperature range from +5 deg. C to + 200 deg. C. The main application

of these types of Heat Pipes are in Injection Moulding, Compression / Transfer

Moulding and Rotation Moulding,

Spiral Screws.

For Die-Casting Dies:

Heat Pipes having temperature range from +5 deg. C to + 350 deg. C. The main

application

of these types of Heat Pipes are in Die-Casting, Spiral Screws in plastic moulding.

It is advisable to order the Heat Pipes suitable

to the applications temperature range. If the Heat Pipe gets heated

above its operating temperature, it releases a small amount of non-toxic gas

and becomes inoperative.

Material of construction: Copper

/ Stainless Steel

How to get the best out of Heat Pipes

It is essential to design cooling system in mould design

stage only. Normally water-cooling is given after mould

is complete. Due to mould elements like return pins, ejector pins, inserts,

alien bolts, etc. only limited space is

available for providing water channels. Mould cooling controls productivity

of mould and hence one should think

about cooling design first and then should give ejector pins, return pins, alien

bolts, guide pillars and other standard

items in the vacant places.

Selection of correct dia. and length of Heat Pipe is important. Based on product

raw material, weight of the product

and desired cycle time, the number of Heat Pipes required for a particular mould

is decided.

Once size and quantity of Heat Pipes is finalised, installation of Heat Pipes

in the mould needs to be done accurately

to get maximum efficiency.

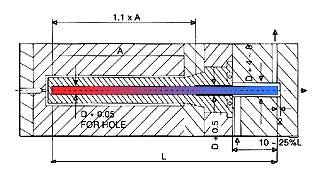

Guide Lines of Heat Pipe Installation

| • Select the largest

dia. of Heat Pipe considering core strength. • Drill and ream the hole to get 0.05 larger hole than Heat Pipe diameter. Scrub the hole with solvents to remove dirt and oil. • Water to be circulated on 10 to 25% of Heat Pipe length. • Do not cut or pierce Heat Pipe. This will make it inefficient. • Before inserting Heat Pipe in the hole, coat uniformly with installation paste over entire length except the portion in which water is circulated and insert with gradual rotation of Heat Pipe to displace air from the hole. • Do not put any packaging over Heat Pipe in case hole becomes oversize. Use higher size Heat Pipe. • Position inlet and outlet of water to get turbulent flow over Heat Pipe cooling end. • Position the colour end of Heat Pipe into water line |

|

Heat Pipe Application Guide

Heat Pipes are widely used for improving cooling efficiency

of injection moulds and Die casting dies all over the world.

This method of cooling has helped reduce cycle time, reduce rejection and improves

quality of product. Sketches given

inside the folder describe various applications where one can confidently use

Heat Pipes. These are taken from actual

examples of moulds, which are in production all over India. In conventional

water cooling, effectiveness of water

cooling goes down due to rusting, blocking of cooling channels. In case of Heat Pipes since water is not circulated

directly in the core, cooling efficiency remains the same throughout the life

of the mould

Heat Pipe Standard Range Details

Heat Pipes are readily available in standard diameters from

3 to 12 mm and in lengths from 50 to 250 mm shapes

as shown in the chart. Other sizes from 2 to 24 mm and in any lengths are also

available on request.

If you need any further information and help in

solving your mould cooling problems; our technical service people will

assist you.

Note: All Heat Pipes are 100% tested to highest

international standards. Now all major plastic

companies and mould

makers have started using our Heat Pipes. Some of them have changed over from

imported Heat Pipes to our high

performance Heat Pipes, which are available at competitive rates.

|

DIA Ø mm

|

LENGTH (mm)

|

|||||||||||||

|

A

|

B

d |

C

Tp |

D

L1-L D-d

|

E

L1-L2-d |

F

B W |

50

|

75

|

100

|

125

|

150

|

175

|

200

|

225

|

250

|

|

3

4 5 6 8 10 12 |

-

- - 3 4 6 8 |

-

- 3-3 3-3 6-6 8-8 8-8 |

PLEASE

STATE |

PLEASE

STATE |

PLEASE

STATE |

*

* * * * * * |

*

* * * * * * |

*

* * * * * * |

*

* * * * * * |

*

* * * * * * |

*

* * * * * * |

*

* * * * * * |

*

* * * * * * |

*

* * * * * * |

Good Reasons To Use Heat Pipes:

Reduce cycle time

Eliminate hot spots

Reduce wastage

Improve product quality

Increase mould life

Eliminate core clogging

Cut mould and Moulding costs

Upgrade old moulds

Use damaged moulds